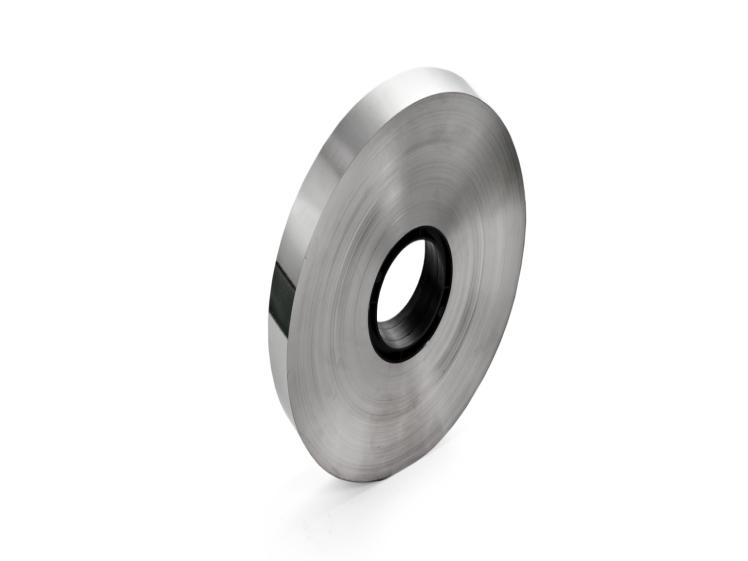

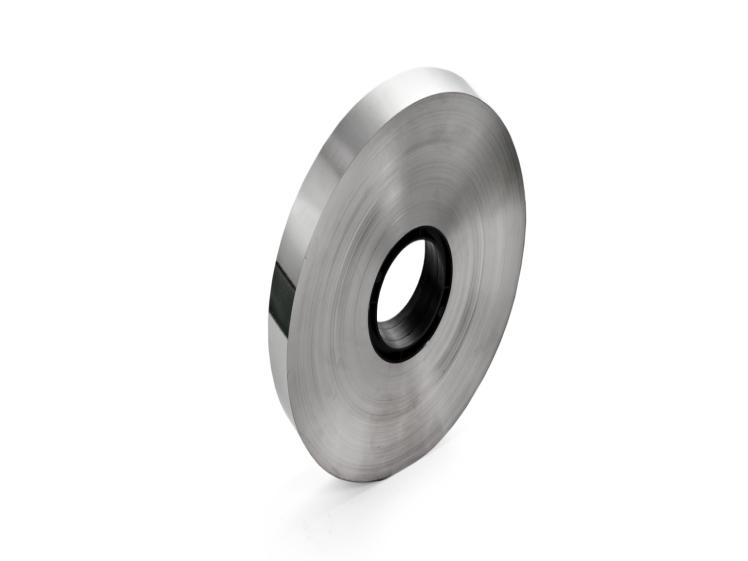

Product Name | Iron-Based Amorphous Single-layer Strip 1K101P1 |

Origin | Hongwang, China |

Standard | GB |

Thickness | 0.025(mm) |

Length | Customized |

Width | 120/142/170/213/240 (mm) |

Application |

Electromagnetic Conversion Equipment |

Certificate | CE, ISO9001 |

Processing | Rapid Quenching

|

Sample | Available |

Delivery | 7~25 days |

Packing | Wooden Pallet |

MOQ | 1.5 MT |

Business Code | Factory Directly Sell |

APPLICATIONS

APPLICATIONS

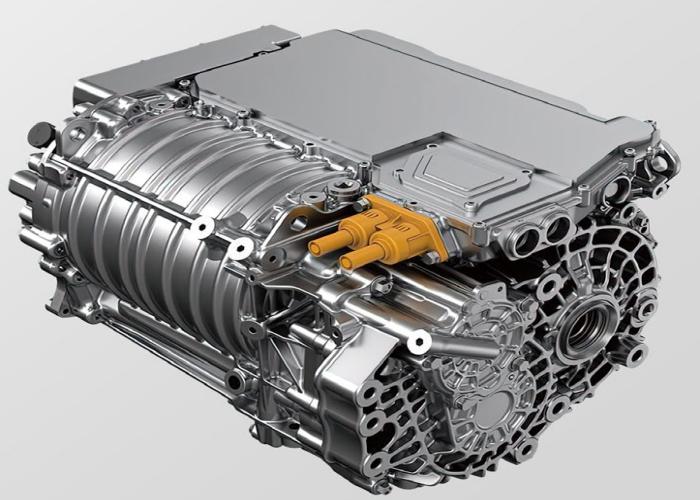

The 1K101P1 iron-based amorphous single-layer strip developed by Hunan Hongwang New Material Technology Co., Ltd. is suitable for use in electromagnetic conversion equipment such as inverter reactors, transformer cores, wide constant permeability inductor cores, PFC inductor cores, medium frequency transformer cores, distribution transformer cores, and amorphous electromagnetic shielding foils for digital electronics.

CHARACTERISTICS

1. Magnetic Properties

Grade

Theoretical

Density

Kg/dm3

Electromagnetic Properties

Guaranteed value

Typical value

Magnetic flux density

B800

T

Total Loss

P1.35/50

W/kg

Apparent

Power

Ss1.35/50

VA/kg

Magnetic flux density

B800

T

Total Loss

P1.35/50

W/kg

Apparent

Power

Ss1.35/50

VA/kg

1K101P1

7.25

≥1.56

≤0.14

≤0.16

1.60

0.125

0.147

Note: (1) The specific total loss and specific apparent power are measured using ring-shaped specimens formed by winding strip materials.

(2) B800 refers to the magnetic flux density at a magnetic field strength (H) of 800 A/m; P1.35/50 refers to the specific total loss measured at a magnetic polarization intensity of 1.35 T and a frequency of 50 Hz; Ss1.35/50 refers to the specific apparent power measured at a magnetic polarization intensity of 1.35 T and a frequency of 50 Hz.

2. Lamination Factor

The thickness of the strip material is 25μm, with a lamination factor of over 88%.

3. Ductility

The toughness value shall not exceed 4.0 (refer to Appendix D of GB 19345.1-2017 for the measurement method of toughness of amorphous alloy strip).

OVERALL DIMENSIONS

1. Coil Weight: 200--400 kg

2. Coil Diameter: Inner diameter of strip material 225mm±3mm

FAQ

Q1.About the complaint,quality problem,etc aftersales service,how do you handle it?

A1.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

Q2.How can you ensure the quality of your product?

A2.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Q3.About the complaint,quality problem,etc aftersales service,how do you handle it?

A3.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

HONGWANG SHIPPING PACKING

1 Inner ring paper tube

2 Spray rust inhibitor on the end face

3 Seven character galvanized isolation sheet

4 Outer roll inner and outer PE corner protector

5 Plastic steel strapping

6 Gas phase rust proof paper

7 PP film cover

8 Inner and outer circle paper corner protectors

9 Galvanized corner protector

10 Packing tape

11 PE outer protective plate

-

No Data